1. TRANSPORT

Profiled trapezoidal sheets with or without insulation are transported in dry means of transport, covered with protective textile tarpaulins which are water resistant and do not leave paint. Cargo shall be fixed to the means of transport with tension systems.

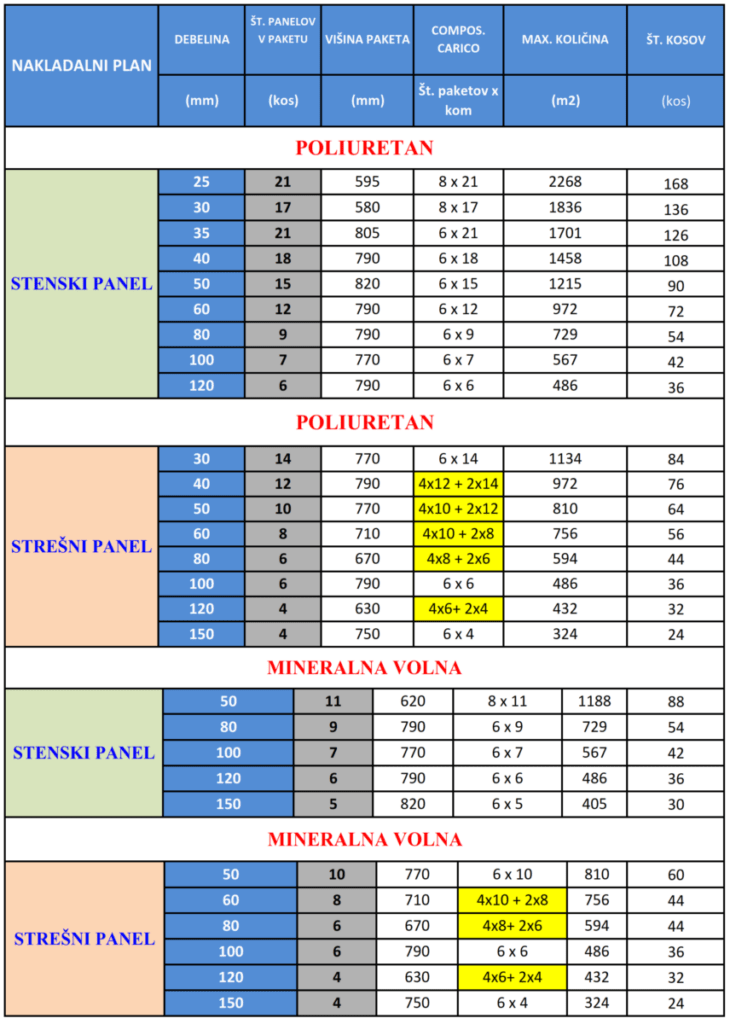

2. LOADING PLAN

3. UNLOADING WITH A CRANE

Packages shall always be attached at two points, which are at least a half package length apart when lifting. We recommend using synthetic fibre belts for lifting (nylon) with a width of at least 10 cm so that the load is evenly distributed and deformations are prevented. Spacers shall be used below and above the package, which is made up from straight and strong elements from wood or plastic, which prevent the belt to get into direct contact with the package. The spacers shall be at least 4 cm longer than the width of the package and shall be at least as wide as the belt. Pay attention that the fixed points and the angle does not change during lifting, and that all operations are carried out carefully and with due diligence.

4. UNLOADING WITH A FORKLIFT

When unloading is carried out with a forklift, pay attention to the length of packages and their possible folding with the aim of preventing damage to the bottom part of the package. This is why we recommend the use of forklifts, which are adapted for moving panels or similar products. If packets are unloaded to a roof beam, work shall proceed in the scaffolding area; otherwise, workers shall consult with the construction site manager. On tilted roofs, packages and sheets shall be protected from shifting. When the goods are delivered, the Buyer shall verify the quantity and whether there is visible damage to Goods. In case of derogations, he shall immediately notify the Seller in writing.

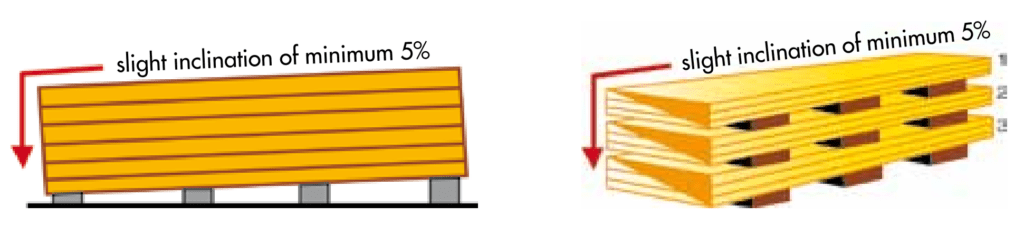

5. STORAGE

Packages shall always be lifted from the ground in the warehouse and at the construction site. Packages shall always be placed on a suitable base (wood, styrofoam, etc.). Packages shall preferably be stored in dry and well-circulated areas as to prevent condensation and consequent oxidation on elements less exposed to air. Panels with galvanised sheet metal shall be stored in dry and well-circulated areas. If this is not possible, we recommend opening packages and exposing panels to air (by separating them); if panels remain in the package, the zinc coat can oxidise (red-white) within a couple of days because of galvanic corrosion. Packages shall be stored with a small incline, which enables water to flow from them, especially when they are stored outside. If storage outside is prolonged, we recommend covering packages with protective textile tarpaulins which are water-resistant and do not leave paint. This protects them from humidity, dirt and sunlight.

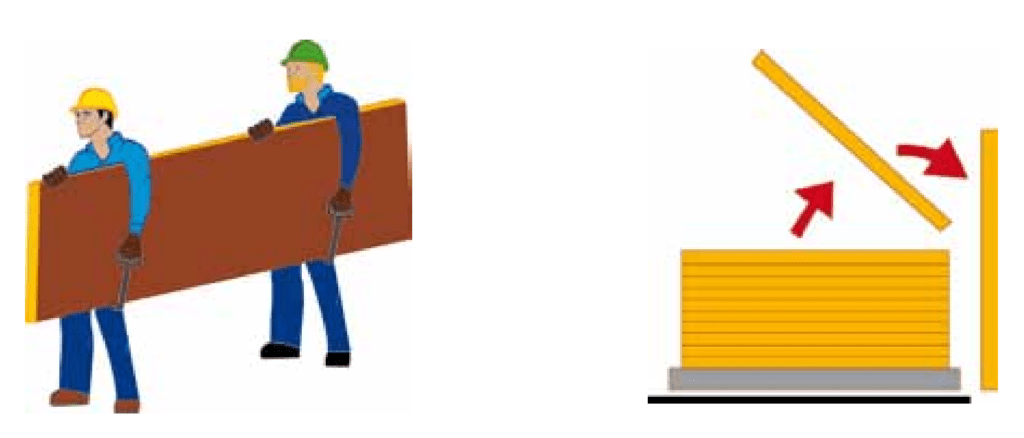

6. HANDLING PANELS

Use suitable personal means of protection (gloves, working boots, etc.) in accordance with valid legislation when handling panels. Manually moving individual panels shall always be carried out by lifting the panel, while dragging the panel on the lower part of the package is prohibited. Depending on the length, at least two persons shall carry out transport. Handling tools and gloves should be clean as to prevent damage to panels.

7. ASSEMBLY

Personnel responsible for mounting the panels shall be qualified and shall know correct techniques for performing work in accordance with valid norms. Individual panels shall be carefully transported to the place of assembly. Panels may not be ground or thrown. Personnel working at the construction site shall be equipped with working shoes with soles, which will not damage the external surface. Prior to assembly possible oxidation residue shall be removed with a clean and damp towel. Use suitable equipment for cutting at the construction site (handsaw, sheet metal shears, etc.). Prevent the production of sparks and overheating of materials during cutting. Profiled sheet shall be cut in a manner so that the external side faces downwards. When drilling all chips shall be removed immediately from the surface of the panels.

All chips, which are produced during drilling and cutting, shall also be removed. For tightening screws a torque screwdriver is required. For roofing with elements without interim joints (coverings) the slope shall generally amount to at least 7%. For smaller slopes additional lateral sealing shall be installed.

8. PREVIOUSLY PAINTED METAL LININGS

Previously painted metal linings shall be delivered with a protective PVC film, which prevents damage to previously painted parts of the panel. The protective PVC film, which is covering previously painted panels, shall be completely removed during assembly and within two months from the date of manufacture at the latest. If panels are sold from stock, the film shall be removed immediately. Additionally, we recommend not exposing foil protected panels to direct sunlight. For panels, which were ordered without a protective PVC film, special care during moving and assembly is required. The manufacturer shall not be liable for damages caused by incorrect transport, warehousing, handling and assembly.

- QualityWe offer our customer products and services of highest quality.

- TraditionWith many years of experience, we are able to manage the most demanding of projects.

- Sales quantityWe have sold more than 6 million m2 of roofs and facades.

- DevelopmentWith a continued development, we are ensuring the satisfaction of our customers.